Asset Tracking and Material Flow Analysis in Real-time

Real-time asset tracking is the process of tracking a physical asset in a facility to define its location. An asset can also be materials or products that are being tracked to monitor their flow throughout the production process. The goal of tracking assets is to maximize asset utilization, prevent asset misuse and optimize their role in all processes.

How Does Real-Time Indoor Asset Tracking Work?

Each asset that needs to be tracked is equipped with a localization tag that transmits a signal to anchors attached to the ceilings. Often the tags are not attached to a product or material but to the pallet holding it. The anchors at the ceilings then send the signal received from the tag to the RTLS server to calculate the assets’ positions in real-time and with 30 cm accuracy. To discover more about how UWB-powered indoor positioning works, please visit our UWB RTLS page.

The Benefits of Real-time Asset Tracking

Full Real-time Visibility of Assets and Inventory

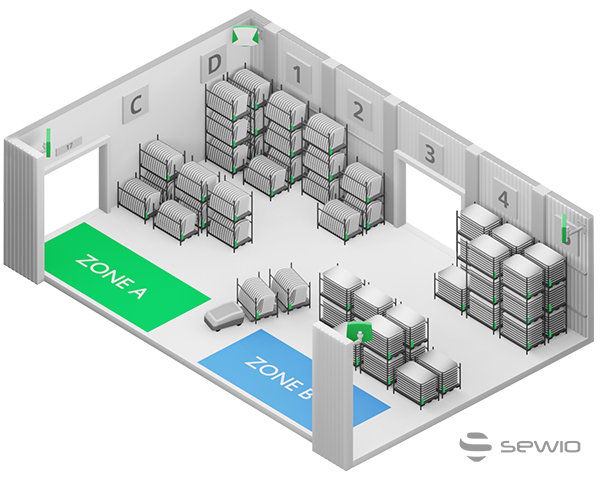

Sewio RTLS provides a full real-time visualization of every asset, tool and material across your entire facility. All tracked assets are visualized on your facility plan with one-foot (30 cm) accuracy and displayed in real-time on any device. Knowing exactly where assets are greatly reduces the time spent looking for missing or misplaced assets or all rejects from a single batch.

Having full insights into where assets were in the past and what their flow across the facility was helps to plan processes better, monitor inventory, reduce search times, limit bottlenecks and streamline workflows.

Triggers Based on Real-time Asset Locations

In the industrial world, the location of a material or asset often defines its production stage. Sewio RTLS provides virtual geofencing, allowing you to set an unlimited number of virtual zones that correspond to various production stages. The location of an asset inside or outside the zone can then automatically trigger a desired action.

A good example is the automatic booking in/booking out of a material in a milkrun process as it is leaving one facility to another. Zone Watch, Sewio RTLS’s advanced virtual zone creator, gives users full control and the power of flexible configuration for defining a zone’s logic without the need for programming.

Real-Time Tool Tracking and Their Configuration based On Location

By having real-time asset visibility, the operators and managers both know if the right tool with the right configuration and right occupancy status is at the right place. At the click of a mouse, staff can view the location and status of the tool with one-foot (30 cm) accuracy across the whole facility, eliminating the wasted time of a manual search.

Another use case represent the automatic configuration of the tightening torques at nutrunners based on the proximity of a particular car body and a particular nutrunner preventing the wrong tightness, which results in slowing down or stopping the assembly line, creating significant costs.

Tag-less Asset Tracking Using Overhead Crane Tracking While Increasing Safety

Assets or materials and their flow can also be tracked indirectly by tracking the real-time position of the overhead crane’s hook that is manipulating them. The material is identified anytime the hook loads it and then it is tracked by tracking the hook until the unload and the data is synced with the WMS. Not only is the material flow monitored but also unloads to incorrect positions are prevented.

The same infrastructure can be used for employee tracking, increasing the safety of the workers in place by automatic alerts to the crane operator’s screen when anyone gets in close proximity to the hook.

eKanban for Material Flow and Production Planning and Monitoring

Using Sewio RTLS, paper Kanban cards can be replaced by digital eKanban cards that can hold the same information and feature a UWB tag for the precise real-time position of the card. Through the digitalization of the Kanban process, the lead time is shortened, fewer employees are needed to cover the operation, the inventory size is right-sized, the manual-entry errors are limited and the full real-time visibility of the processes is gained.

Read more about how eKanban for Material Flow Analysis enhances efficiency and productivity in industry.

Digital Work Orders for Searching for Assets in Real-time

A short lead time is a crucial aspect of success in bespoke (also known as made-to-order) production models. With Sewio RTLS, you can track and trace any assets and find their exact locations on your facility’s maps in real-time. The current paperwork orders are simply replaced by digital work orders carrying the same information, however, they are extended with real-time location and other data types based on the sensors used.

Discover more about how RTLS helps to shorten lead time, eliminate wasteful activities and streamline audits.

Tag-less Asset Tracking via Tracking Handling Vehicles

In scenarios where hundreds to thousands of assets (e.g., pallets) are being transported by vehicles such as forklifts, you can achieve a better project ROI by tracking a smaller number of forklifts rather than all the pallets that the forklifts are manipulating. The trick here is to identify the pallets with cameras and barcodes or NFC technology during the loading, pair that information with the forklift, and then simply only track that forklift to be aware of the location of the pallet.

By tracking forklifts, the full real-time visibility of the material’s location and its flow within the facility is achieved while keeping the costs of your indoor tracking project at a minimum.

Quality Management Using Asset Tracking

Manufacturing quality is now an absolute requirement and a critical factor in market differentiation. An inevitable part of ensuring manufacturing quality is measuring the correctness of the production processes.

This can be achieved by tracking the position and time of each product during the production process to check for its correctness. As also the Z-axis, the height of the product, can be tracked as well as the time period for which each product has been exposed to a coating, you can ensure their consistent and high quality.

Improving the Picking Process by Asset Tracking

Knowing in real-time where your assets are, both in the horizontal and vertical space, improves the processes your workers use to find, pick and put the correct component in the right location. The audio system navigates workers to take the optimal route to the asset in the best picking order possible.

If a worker is about to pick an asset that is substitutable from multiple options, the system selects the one in closest proximity. As a result of this, the workers increase their picking rates and save time.

Real-life Case Studies of Asset Tracking

Sewio Partners Delivering Asset Tracking

The Benefits of Using Sewio RTLS

Rechargeable UWB RTLS tags for employee tracking with a battery life of years.

A fully scalable solution that allows you to customize existing tags, add thousands of tracked assets and increase the coverage as your needs grow.

30 cm accuracy, which allows the full flexibility and variability of virtual zones without any changes of infrastructure.

Sewio RTLS is fully industry certified to guarantee reliable and scalable performance in even the harshest environments.

One flexible infrastructure suitable for multiple existing and future business cases.

We ensure you find the perfect certified and well-trained partner in your region for your project based on customer/partner fit.

Ready to Boost Your Efficiency through a Real-Time Asset Tracking System?

| “ | Sewio provides a reliable and scalable solution for asset tracking using ultra-wideband RTLS. The API to access the system and the collected data, in particular, offers great possibilities to integrate it with our and also the customer’s systems. The advantages of the system are not only linked to the technology, but also to the passion of the Sewio team to support us in complex project situations and streamline the delivery.” Georgios Karachos

|