Employee Location Tracking System for Safer People and Smarter Decisions

Manufacturing relies on people, not just machines. And every accident is one too many. Yet without real-time visibility, even the best teams are left guessing. Our real-time locating system (RTLS) removes those blind spots. Optimize shift flows, protect lone workers, speed up evacuations! Because in your plant, safety isn’t paperwork. It’s a priority.

Knowing the Employee Location Is Crucial

If these sound familiar, you’re not alone. Many manufacturers face the same challenges:

• They don’t know where everyone is in large or complex buildings

• Mustering drills take far too long

• It’s hard to identify why processes get delayed

• Slow manual headcounts and paperwork

• Pressure to meet safety KPIs and lower incident rates

But there’s a better way.

Real-Time Locating System Keeps Workers Safe

A real-time locating system (RTLS) shows you the live and precise location of your workers, so you can prevent accidents and quality issues, and optimize operations.

- Fast and smooth evacuations

- Automated alerts to protect workers

- Automated attendance tracking

- Location data for continuous improvement

The Benefits of Employee Location Tracking System

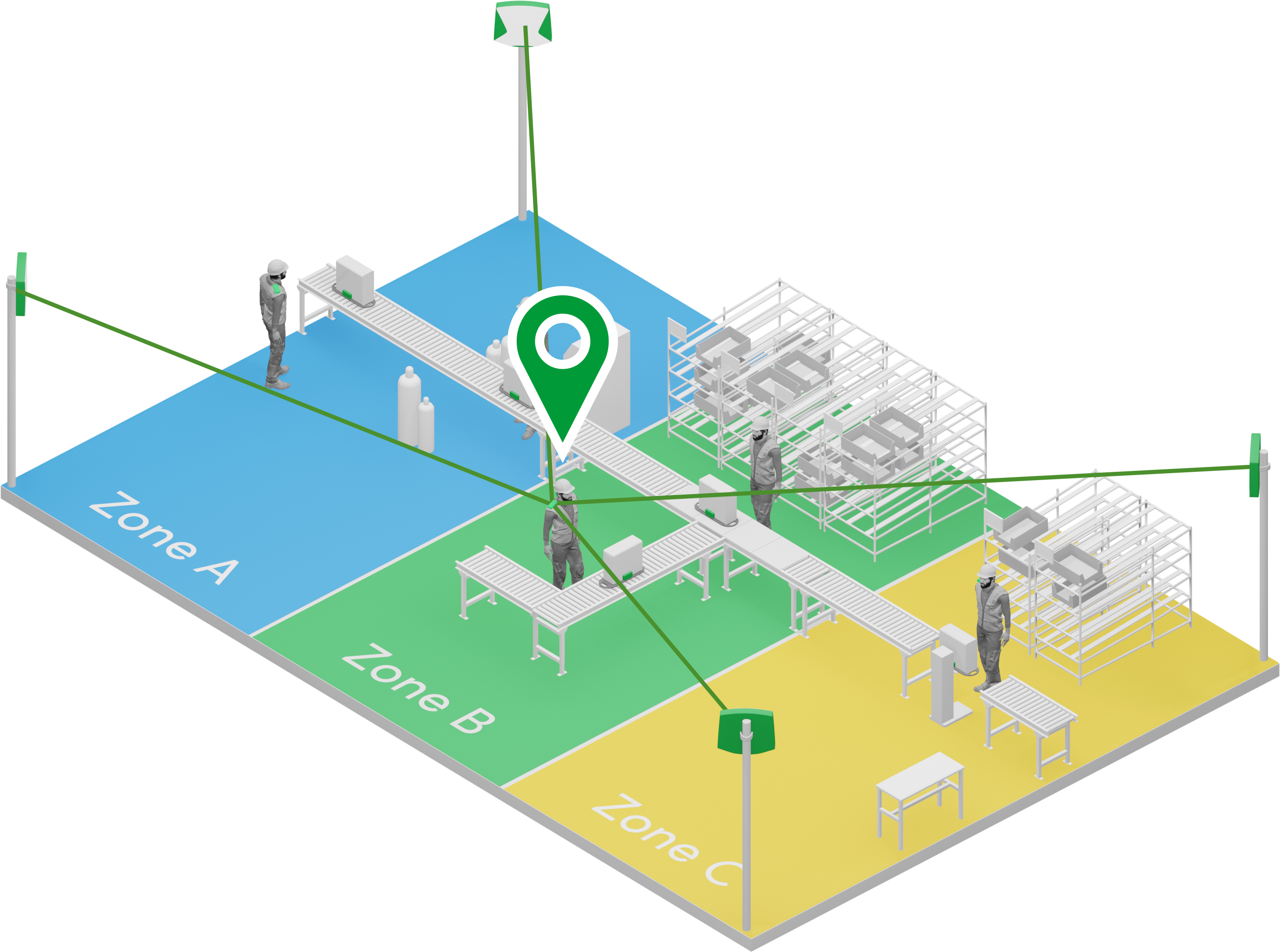

How Worker Location Tracking Works

Simply put, RTLS turns real-time location data into a safety and efficiency tool.

Each employee wears a small tag, typically clipped to their belt or worn as a wristband. These tags send out short radio pulses detected by anchors mounted to the walls around your facility. The Sewio RTLS software collects the location data and displays it on an intuitive live map. You can review it from your safety control room, on managers’ PCs, or even mobile devices.

Location data can be fed to your HR, BI, access control, and many other systems. It can trigger automatic actions like alerts or opening doors only to authorized personnel.

Our technology is used by more than 300 companies, and it’s well tried and tested even in large, complex, or metallic industrial environments. The system is powered by:

Four Steps to Keep Workers Safe

Employee Location Tracking that Respects Privacy

Tracking employees may raise privacy concerns. But we’ve got it covered. Our RTLS is built with safety as the top priority. It helps evacuate faster, shut down machines in emergencies, and prevent collisions in busy zones. And yes, the same data can help boost productivity or recognize top-performing teams, but only with full transparency and clear boundaries.

Our RTLS complies with some of the world’s strictest data laws, including the EU’s GDPR. Tracking is limited strictly to production areas and never offices or break rooms. To get everyone in the company on board, many of our customers start with a voluntary pilot, so teams can see for themselves what’s tracked and why. And if you need legal guidance, we can help you navigate every step with confidence.

Unlock Business Transformation with Employee Location Tracking

RTLS needs a single infrastructure to drive business value in multiple ways.

Employee Location Tracking Use Cases

Quicker Mustering Time

Even the most up-to-date paper-based mustering processes take a significant amount of time before finally securely discovering who is safe and who is still missing. The complexity of the process multiplies with the size of the facility, the number of floors within buildings and the amount of assembly (=muster) points. Digitalization of the mustering process significantly helps to decrease the time needed to complete it and brings real-time updates of those accounted for and those persons still missing, together with an instant evacuation list.

Faster Rescue Access to Injured Persons and Panic Buttons

In case of emergencies such as fires, explosions or gas leaks, the exact location of affected personnel is known, dramatically reducing the time necessary to rescue them. The location tags are also equipped with a “panic button” with a “man down” feature. In case of a heart attack, incapacitation or injury, the affected person can request help immediately by pressing the panic button, sending an alert with their current position to the control room and speeding up the rescue operation.

Improving Emergency Drills through Analysis

Having real-life historical data of the movements of all people and, eventually, also key objects during emergency drills helps to verify the validity of evacuation routes, reveal blockers, both in the paths and the processes, and streamline them. Facility emergency managers can use these real-life-based insights to handle special emergency scenarios in the best possible way, maximizing the safety of all people at the facility.

Geofencing and Decreasing Restricted Area Movements

Sewio RTLS’s geofencing feature allows you to set any number of virtual zones, representing geographic boundaries, and enable the automatic triggering of a response when a tracked tag enters or leaves an area. For example, when a person enters a warning zone, the IO link enabled light tower can signalize a possible danger and also alert the facility manager about the violation. If the person continues into the dangerous zone, the machine that represents a risk to the person’s health can be automatically stopped, preventing any threat of injury.

Increasing Safety of Moving Entities with Dynamic Tag Zones

Dynamic Tag Zones enable alerting, reporting and tracing based on the proximity of two moving entities and the duration of their encounter. This feature unlocks employee safety scenarios where the proximity of two moving objects can create alerts and warnings. For example, when a person is walking down an aisle and a forklift is approaching them from around the corner the dynamic tag zones make these entities located around corners or behind aisles “visible” to each other and can alert them to prevent incidents or fatal injuries.

Increasing Safety by Creating a People-Aware Environment

Certain safety use cases combine people tracking with tracking moving objects, such as tracking forklifts, to prevent injuries. At unloading areas, forklifts are busy with their operations and at any time, anyone, such as the truck driver who just came with new cargo, can suddenly appear in the proximity of the forklift. By tracking both the forklift and the truck driver, the system can automatically alert the forklift operator on their screen that a person (the truck driver) has suddenly entered their operational zone to prevent a fatal injury.

Safety and Health Sensors Additional to RTLS

The tracking badge or tag worn by a person can feature additional sensors such as a radiation dosimeter, thermometer or carbon dioxide (CO2) concentration sensor. This then can inform the person immediately if they are being exposed to unhealthy or even risky levels of radiation, concentrations of CO2 or a high temperature for an impermissible period. The information can then be shown on displays within the facility or sent to the person’s mobile device.

Indoor Smart Quarantining Solution to Limit Infection

Respiratory infections, such as flu or coronaviruses, including Covid-19, are a serious health risk and their transmission across the workplace is even easier in a closed indoor facility. Using UWB RTLS, companies track team members on their premises to help prevent the spread of infection by monitoring, with one click, anybody who has come into contact with a newly identified infected person. Those exposed staff members are tested and receive the treatment they need as quickly as possible. This “smarter”, faster and selective quarantining helps to save lives and keep mission-critical operations running at all times.

Human and Machine Real-time Interaction Using a Smartwatch

In this use case, the real-time location of the material handling device (AVG) and the worker is known to the system that controls the production. Once the AGV arrives at the workstation (Zone B), the worker closest to the AGV gets a message on his smartwatch to unload the AGV. Once he has finished his operation, he presses the “End of unload” action on his smartwatch, which triggers the AGV to move to its next location. Having this in place, the waiting times on both sides – machine and human – are reduced, resulting in higher operational efficiency. Similar use case have been implemented in project for Continental.

Indoor People Navigation

Indoor navigation helps people, both employees or site visitors, by directing them to their planned destination in the shortest time and safest way possible. People can be guided by a mobile device, with the tracking tag either on the device or in the visitor badge. This benefit becomes even more important when supporting the movement of visually-impaired people, who can be easily vocally guided to their target spot.

Indoor People-Flow Analytics

People flow heatmaps and spaghetti diagrams show movement density and flow, helping to visualize the flow patterns and display analytics of the movements and interactions of the people and things in your physical space. They reveal the dwell-time patterns and highlight waiting times, allowing an increase of operational efficiency through process, space and workflow optimization. Knowing at which location and zone people spent their time can also be used for automatic workhours reconciliation for subcontractors.